Product performance

Impact resistance: it is one of the most impact resistant thermoplastic plastics, and its impact resistance is 10 to 27 times that of glass and plexiglass.

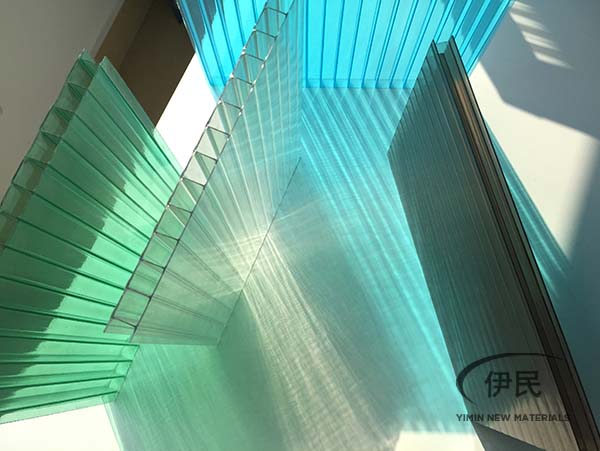

Light transmittance: according to different colors and thickness, the light transmittance can reach 82% to 20%

Weatherability: the surface of the product has UV coextrusion layer.

Heat resistance: the physical properties remain stable in the range of - 40 ℃ to 120 ℃.

Sound insulation: can effectively reduce noise, compared with the same thickness of glass, sound insulation performance can be improved 3 to 4 times. In the world, it is the first choice material of highway noise barrier

Thermal insulation: compared with the same thickness of glass, the thermal insulation performance can be 40% to 60% higher.

Fire resistance: up to GB8624 flame retardant class I (B1) standard.

Light weight: the specific gravity is only 1 / 12 of that of ordinary glass, and it is not easy to break. It saves time and labor in handling and installation, especially suitable for tall buildings.

Easy processing: the bending radius can reach 175 times of the plate thickness, suitable for processing various shapes.

Energy saving of greenhouse board: the thermal conductivity (k value) of sunlight board is lower than that of ordinary glass and other plastics, so that the heat loss is greatly reduced. It is an environmental protection material for buildings with heating equipment.

Anti condensation of greenhouse board: under normal circumstances, when the outdoor temperature is 0 ℃, the indoor temperature is 23 ℃, as long as the indoor humidity is less than 80%, the surface of the material will not be dewed.

Scope of application

Greenhouse / industrial plant, decoration, advertisement signboard, parking shed, passage lighting canopy, commercial building lighting canopy, exhibition lighting, stadium, swimming pool, warehouse lighting roof, commercial factory, stadium lighting canopy and sunshade canopy, agricultural greenhouse, breeding and flower greenhouse, telephone booth, newspaper booth, station and other public facilities, highway sound insulation, advertisement Decoration field.

The corridor Pavilion of garden, entertainment place and rest place;

Interior and exterior decoration of commercial buildings, curtain walls of modern urban buildings;

Aviation transparent container, motorcycle windshield, aircraft, train, ship, automobile, motorboat, submarine and glass military police shield;

The layout of display signs, billboards, advertising booths, telephone displays, etc;

Instruments, meters, high and low voltage switchgear panel and military industry, etc;

Wall, top, screen and other high-grade interior decoration materials;

Noise barriers for expressways and urban viaducts;

Agricultural greenhouses and breeding greenhouses;

Ceiling of modern ecological restaurant;

Bicycle shed, balcony awning and roof rest Pavilion shed in all units or communities;

Installation method

1. Check the framework, the surface must be smooth, no burr, welding scar, etc.; the paint on the framework must be completely dry, no residual volatile solvents.

2. Lay the EPDM special lower adhesive strip on the framework, and pay attention not to contact the adhesive between the adhesive strip and the framework with the sunlight board to avoid corrosion.

3. Place the sunlight plate in place, the gap between the plates must meet the requirements of thermal expansion and cold contraction, and the plate end shall be sealed with special tape. 、

4. Insert the EPDM upper strip into the aluminum profile.

5. Assemble and fix with self drilling screws or other fastening screws.

6. Contact the technical department of the company for details.

Matters needing attention of hollow sunlight board

1. During installation, the construction organizer must clearly understand the text instructions and precautions printed on the protective film, and explain them to the operator, especially the standard of which side faces out. Don't make mistakes.

2. Before installation, do not remove the protective film. Only remove the protective film about 50 mm along the edge line of the plate. Remove the protective film immediately after installation. If it is necessary to continue to protect the plate surface, remove the film first and then cover it again.

3. The viscous substance of the sealing material shall not damage the PC sunlight board.

4. The sealing belt shall have good weather resistance and shall not lose its viscosity and mechanical strength for a long time.

5. Do not polish or use strong alkali to clean the sunlight board, do not use a hard brush to wipe the surface, so as to avoid galling.

Storage and transportation of hollow sunlight board

1. It should be kept indoors and never be exposed to sunlight or rain

2. Stack by hand, the height of stack should not exceed two meters. There shall be no weight on the board and no hard objects between the boards.

3. The storage room should be kept clean, dry and free from dust. Other chemicals should not be stored in the room at the same time.

4. Do not damage or remove the protective film during storage.

5. During transportation, it must be placed on a clean flat pallet with an area larger than the plate. If necessary, it should be properly tied to avoid vibration and sliding. Pay attention to protect the plate edge from damage and keep the double-sided protective film intact.

Cleaning method of hollow sunlight board

1. Wash with warm water below 60 ℃.

2. Neutral detergent shall be used for cleaning, and detergent with corrosive effect on sunlight board is not allowed.

3. It is required to gently scrub with soft cloth or sponge dipped in neutral solution. It is forbidden to use coarse cloth, brush, mop and other hard and sharp tools for cleaning.

4. When there are grease, wet paint, tape imprint on the surface, it can be scrubbed with soft cloth and alcohol.

5. Clean the dirt thoroughly with clean water.

6. Finally, dry and polish the board surface with a clean cloth without obvious water mark.

Particular attention

The unsuitable cleaning agent is alkaline solution, which will corrode the board surface. It is forbidden to use esters, ketones, halogenated hydrocarbons and all substances that can dissolve or swell polycarbonate.